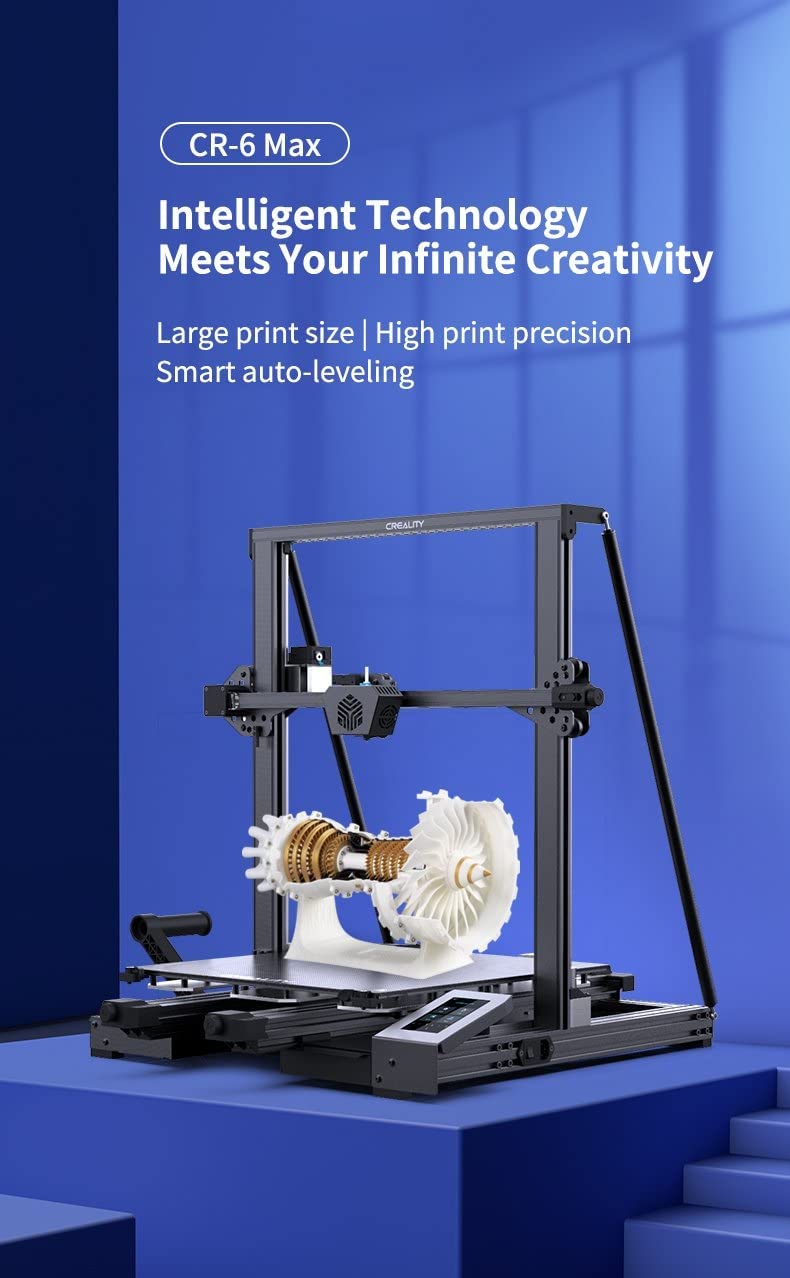

Creality CR-6 Max

- $1,099.99

- $1,099.99

- Unit price

- per

Couldn't load pickup availability

Description

xThe CR-6 Max features the same innovative leveling system as the CR-6 SE, using a force-based sensor. The Max will simply touch the nozzle to the bed at specific points, and a strain sensor on the hot end will detect the exact point at which the nozzle touches the glass.

This system is nice for a number of reasons. For one, there is no extra sensor probe, meaning you don’t need to calibrate any offsets other than the initial Z height to get the right “squish” in your first layer. Also, the automatic leveling system does away with the knobs on the underside of the bed, which will be a relief for anyone who has experience trying to level such large-format machines.

The CR-6 Max will also feature the same 4.3-inch portrait-oriented color touch screen as the CR-6 SE. For users who dislike the dial-operated blue LCDs of the past, this screen will be a welcome inclusion, allowing users to quickly and easily navigate the intuitive menus or check on the print status at a glance.

Handy Inclusions

While not being as portable as the initial design of the CR-6 SE, the CR-6 Max will still feature many of the same quality-of-life features. The built-in tool drawer and folding filament holder both appear to be included on the CR-6 Max, which will be handy for storing the machine and its tools.

Additionally, the CR-6 Max will still have a carborundum (silicon carbide) coated glass build plate, offering the same kind of adhesion that makes the Anycubic Ultrabase so popular. This build plate will be removable, but you’ll have to be careful in doing so due to its massive size.

Further Features

Additional features the Creality CR-6 Max will include:

- Modular Nozzle: Creality designed the nozzle with modularity in mind. Users can disable the nozzle and change the heat block, heat sink, Teflon tube, or the nozzle tip with the included spares.

- Extruder: The redesigned extruder should allow for easier feeding of filament.

- Filament Sensor: The CR-6 Max is equipped with a photoelectric filament sensor detecting any possible filament breakage or runout.

- Resume Print Function: Outages or disconnections should be no problem for the CR-6 Max because it can fully recover and resume the print when it’s back up.

- 32-Bit Motherboard: The CR-6 SE reached one of its stretch goals on Kickstarter, meaning that both the SE and the Max will be delivered with a 32-bit motherboard for enhanced performance.

- TMC2209 Motor Drivers: Another stretch goal, Creality will be adding TMC2209 motor drivers for more precise and quiet printing.

- Mean Well Power Supply: Clarified in Creality’s latest update, the CR-6 SE and CR-6 Max will be shipping with high-quality Mean Well power supplies for extended hardware life and your peace of mind.

- Large Print Bed: 400x400x400

- Choosing a selection results in a full page refresh.