- Home

- HOME

- Cosmic Raceway / CrawLVenture

-

-

- Air

- Go to Air

- Airplanes

- Drones

- Helis

-

Aircraft Parts & Accessories

- Aircraft Parts & Accessories

- Go to Aircraft Parts & Accessories

- Aircraft Motors & Engines

- Propellers

- UltraCote

- Simulators

- Kites

-

- Water

- Go to Water

- IMEX Boats

-

ProBoats

- ProBoats

- Go to ProBoats

- ProBoat Parts List

-

Traxxas Boats

- Traxxas Boats

- Go to Traxxas Boats

- Traxxas Boats Parts List

- Boats

- Boats & Accessories

-

- Ground

- Go to Ground

- Arrma

- Axial

- Bind-N-Drive

- Cars & Trucks, Parts & Accessories

- ECX

- Kyosho

- Losi

- Redcat

- Tamiya

- Team Associated

- Team Losi

-

Traxxas

- Traxxas

- Go to Traxxas

- Traxxas Parts Lists & Exploded Views

- How to Choose the Right Traxxas Car or Truck

- Traxxas 'How To' Videos

- All Traxxas Cars, Trucks, Quads & Boats

- Traxxas Cars

- Traxxas Trucks

- Traxxas After Market Parts & Accessories

- Traxxas Axle Components

- Traxxas Batteries: NiMH

- Traxxas Bearings & Bushings

- Traxxas Body & Accessories

- Traxxas Brake Components

- Traxxas Bumpers & Skidplates

- Traxxas Chassis & Attachments

- Traxxas Differential & Components

- Traxxas Differential and Shock Oil Chart

- Traxxas Driveline Components

- Traxxas Front Suspension & Steering

- Traxxas Hardware

- Traxxas HD Suspension

- Traxxas Hull, Deck & Attachments

- Traxxas LED Light Accessories

- Traxxas Lubricants & Oils

- Traxxas Motors & Electronics

- Traxxas Nitros & Fuels

- Traxxas Radio System, Batteries & Chargers

- Traxxas Rear Suspension

- Traxxas Shocks

- Traxxas Shocks (Ultra Shocks)

- Traxxas Slipper Clutch Components

- Traxxas Spur & Pinion Gears

- Traxxas Steering Components

- Traxxas Suspension Components

- Traxxas Suspension Linkage

- Traxxas Telemetry Sensors & Accessories

- Traxxas Tires & Wheels

- Traxxas Tools

- Traxxas Transmission Components

- Traxxas Transmitters

- Traxxas Turnbuckles & Threaded Rods

-

Horizon Hobby Surface Fluid Chart

- Horizon Hobby Surface Fluid Chart

- Go to Horizon Hobby Surface Fluid Chart

- Fuel

- Shop By Speed

- RPM Parts Compatibility

- Ready-To-Run

-

- Tools & Access.

- Go to Tools & Access.

- Tools, Parts & Accessories

- Accessories

- Adhesives

- Fasteners

- Paint

- Tools

- Tubing

- Tanks & Heavy Equipment

- Team Logo LED Signs & Necklaces

-

- Misc

- Go to Misc

-

Misc. Hobbies

- Misc. Hobbies

- Go to Misc. Hobbies

- Models

- Rockets

- Paint

-

Electronics

- Electronics

- Go to Electronics

- ESC's

- My Wish List

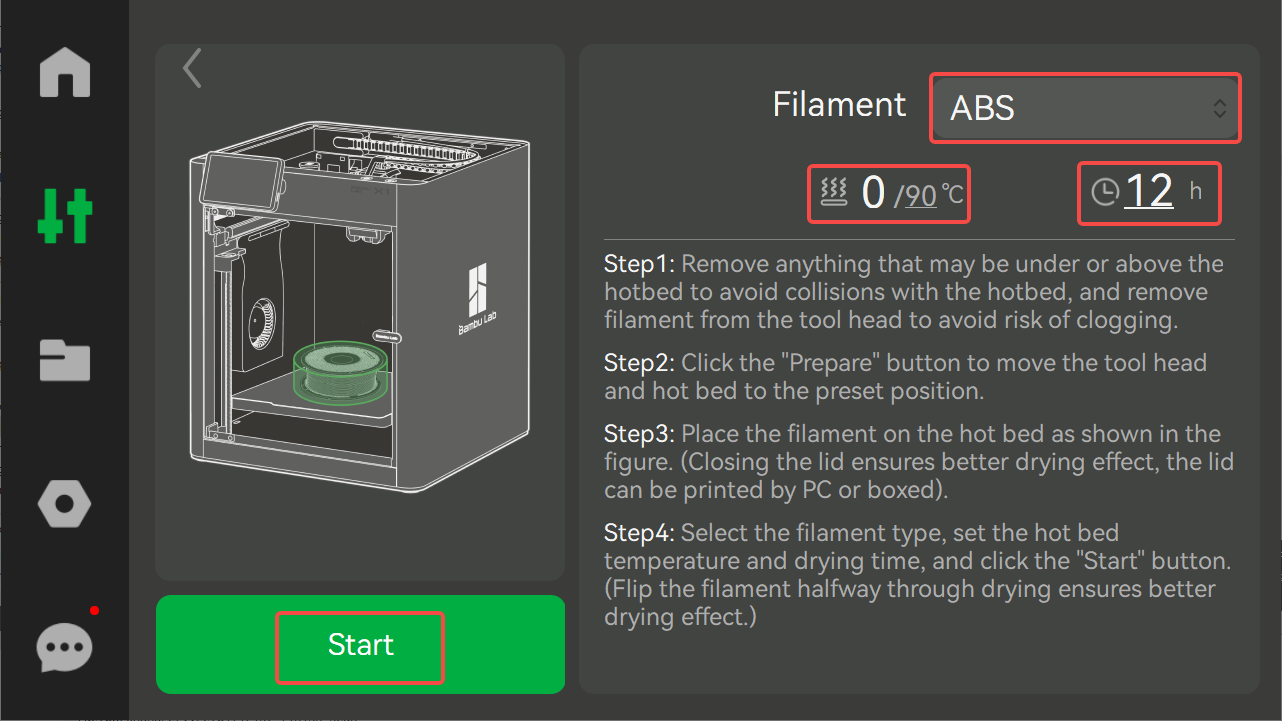

Bambu Filament Drying Cover

After the filament absorbs water, it can cause many problems when printing, such as stringing, easy breaking, etc. To solve these problems, the filament needs to be dried. In order to make it more convenient for users to dry filaments, we use the heating function of the hotbed and the enclosed space in our machine to create a drying environment for filaments.

Download the cover model here: Bambu Filament Drying Cover(Download link )

|

Please carefully follow these instructions and precautions when using them; otherwise, Bambulab will not bear any responsibility for the above risks. Please keep in mind that this filament drying function may involve some problems. These risks include the following: Some third-party spools are not temperature-resistant enough, so spool deformation during drying is possible. There is a risk of clogging the tool head if the hot bed is not in the lower half of the chamber during drying and there are filaments at the hot end. |

|

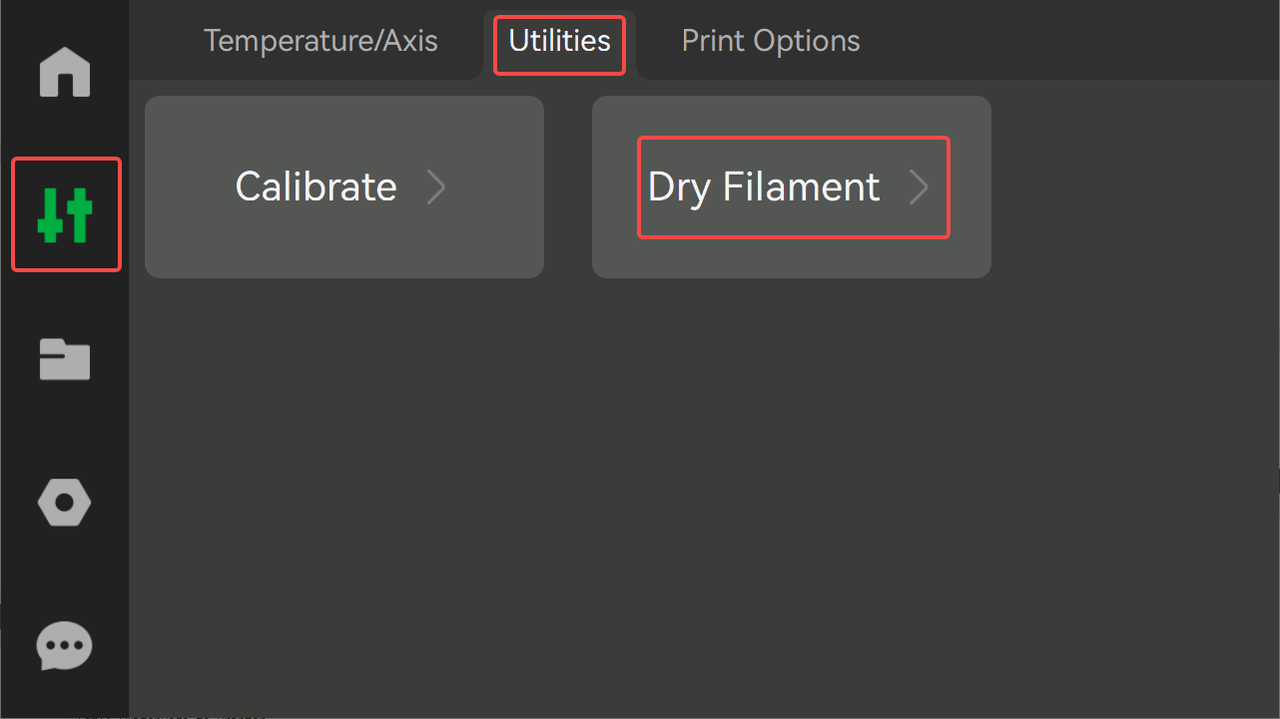

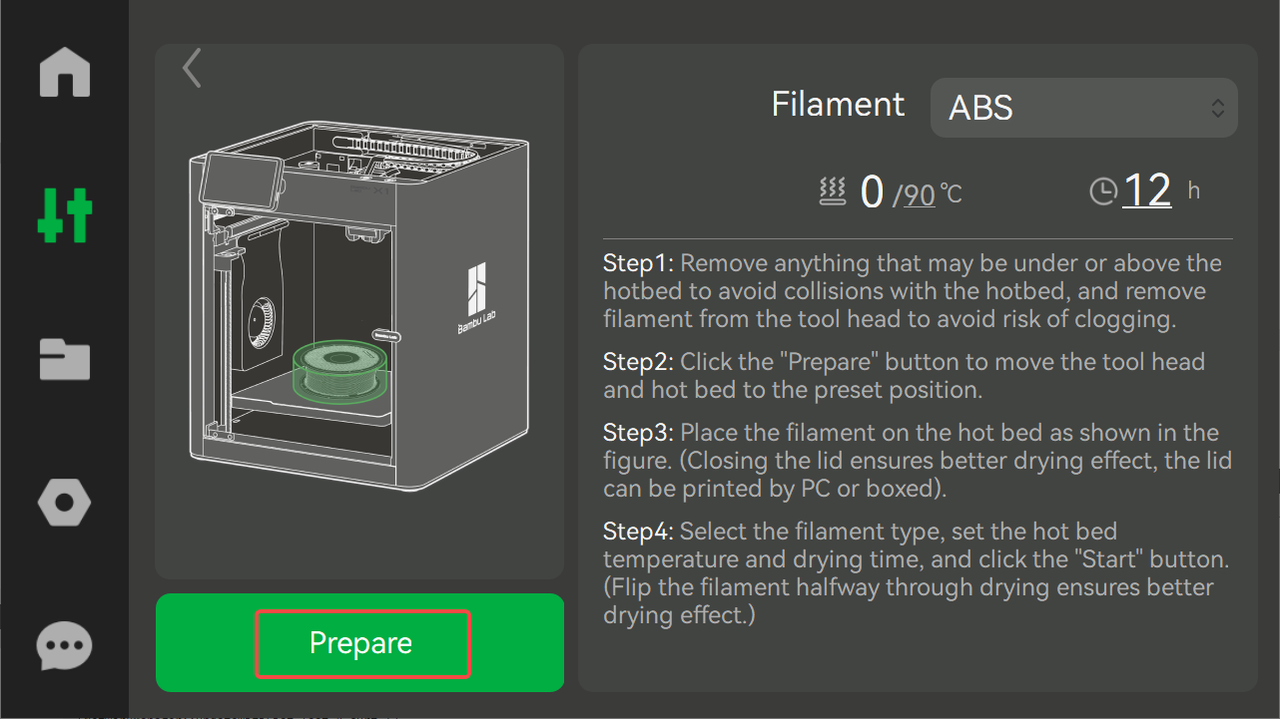

Step 1: Remove anything that may be under or above the hotbed to avoid collisions with the hotbed, and remove the ilament from the tool head to avoid the risk of clogging. Step 2: Click the “Prepare” button to move the tool head and heat bed to the preset positions. |

|

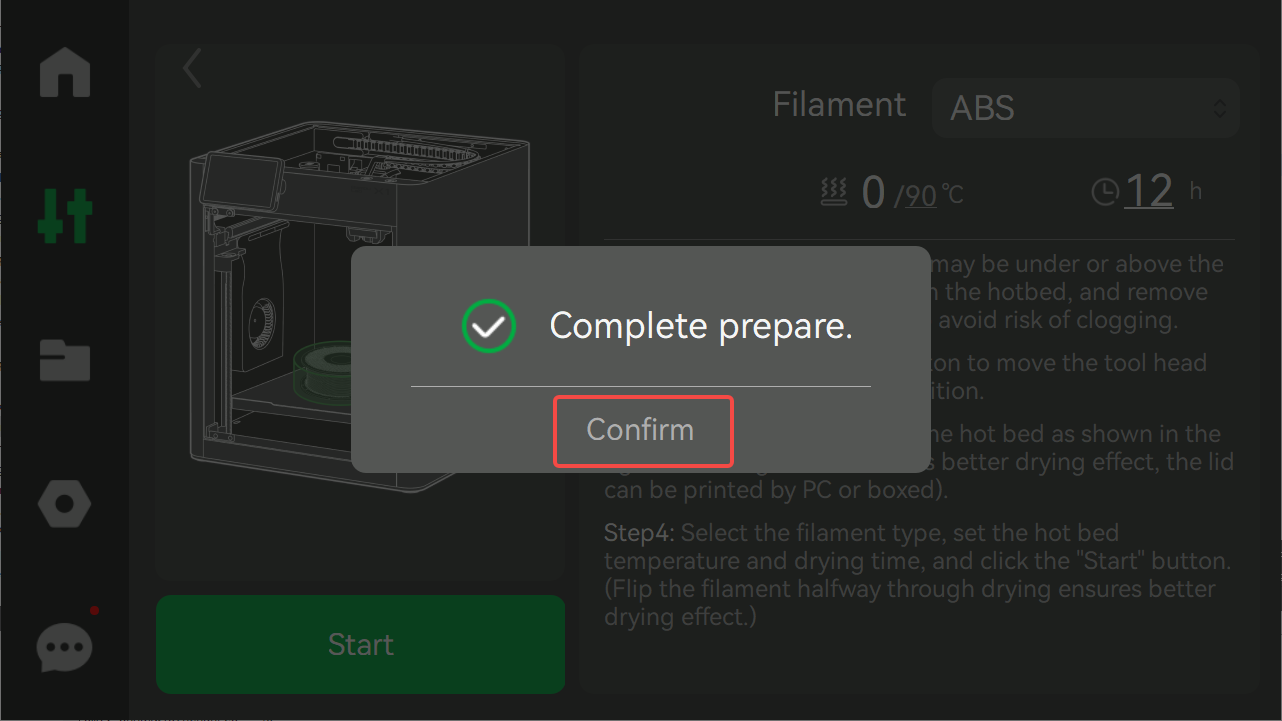

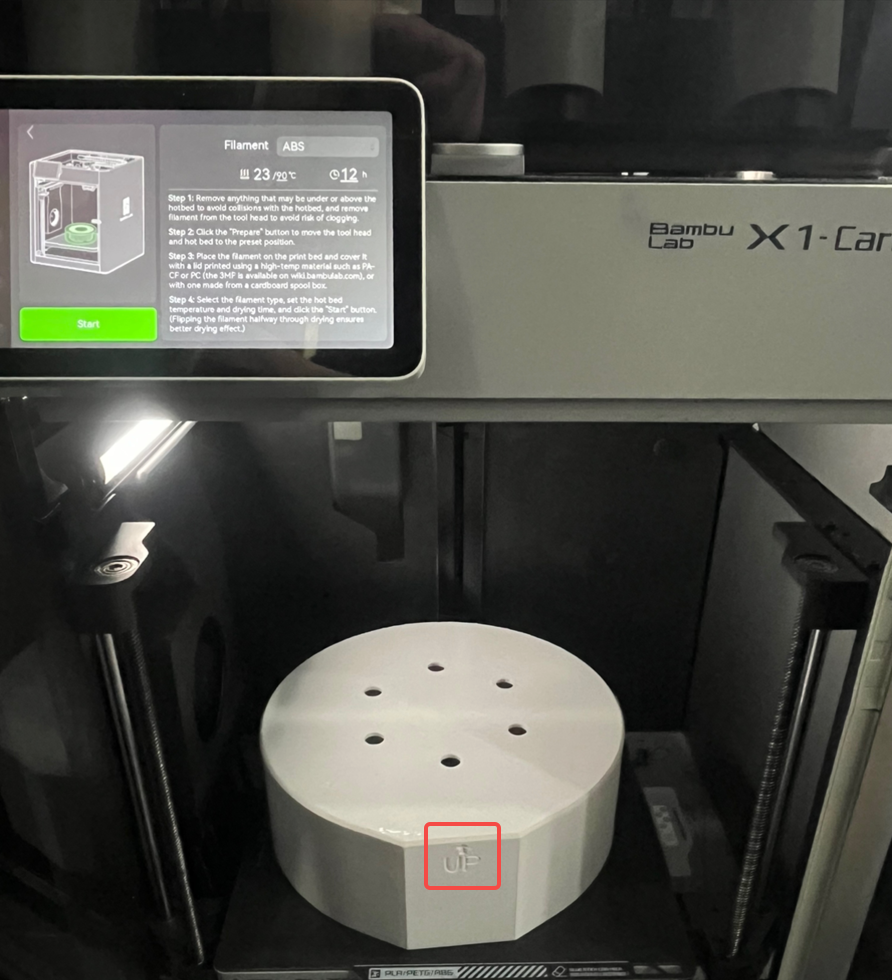

Step 3: After clicking "Confirm", place the filament on the hot bed as shown in the figure below. (Closing the lid ensures better drying effect, the lid can be printed by PC or boxed) Please ensure that the filament to be dried is equipped with the filament spool before putting it on for drying; |

|

|

|

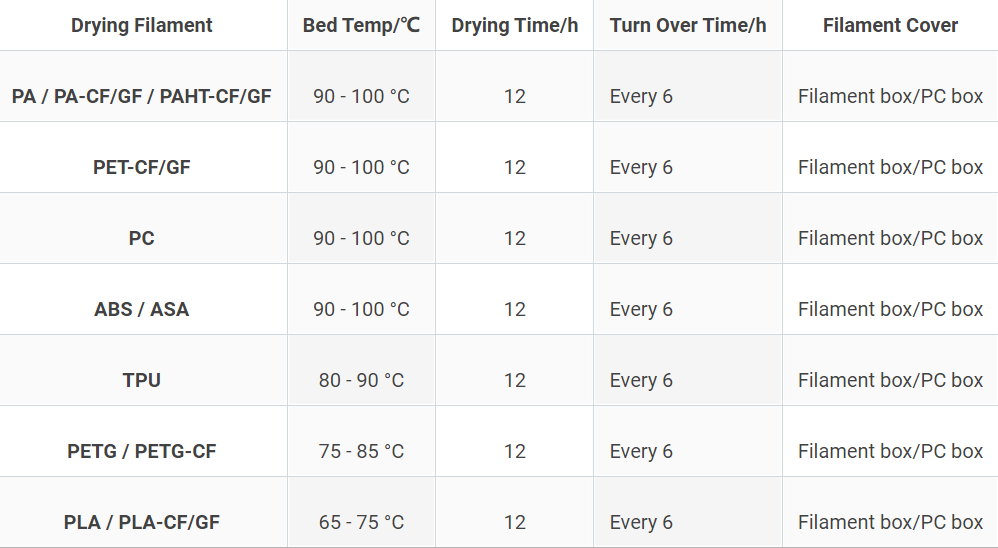

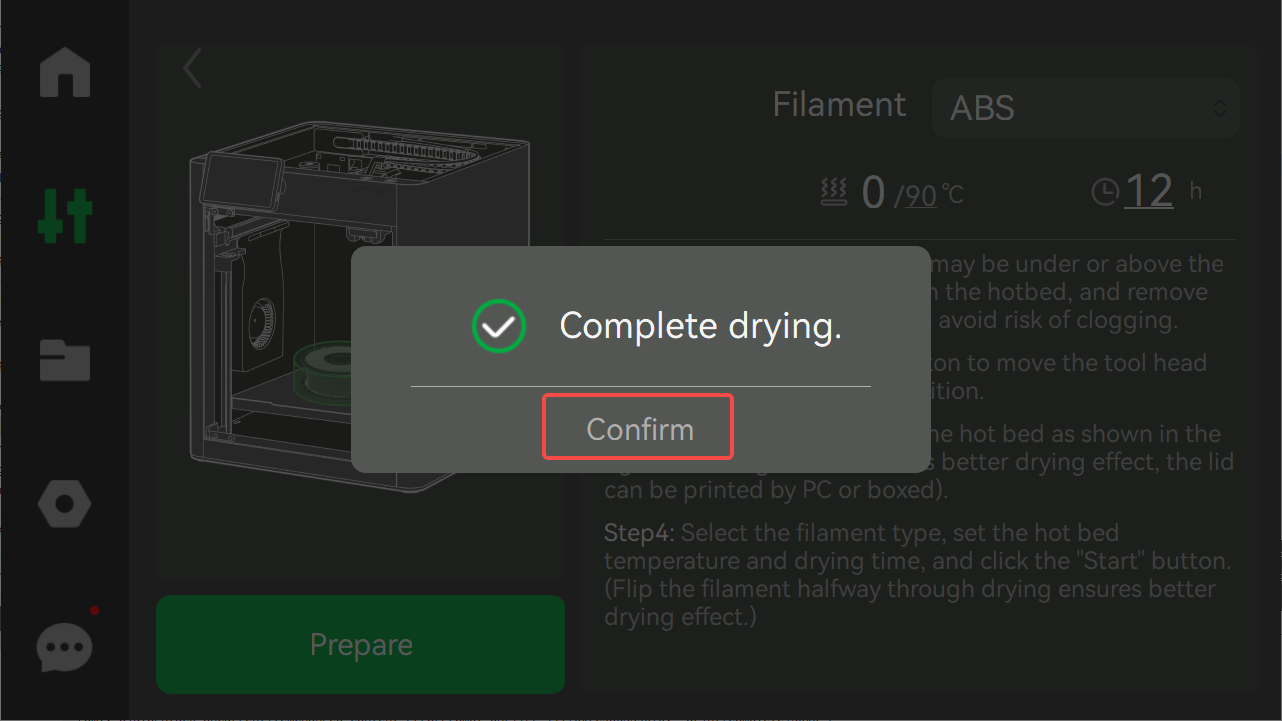

Step 4: Select the filament type, set the hot bed temperature and drying time, and click the “Start” button. (Flip the filament halfway through drying ensures a better drying effect) The drying temperature of various filaments has been preset, and you can refer to this setting when using it (the initial humidity of filament varies, so the drying effect of using the preset parameters will vary); if you believe that the temperature of the hotbed or the time does not meet your actual situation, you can modify it yourself (maximum temperature 90°C, 48 h); If the filament you want to dry isn't present in the preset settings, you can choose one of the preset filaments first and then modify the temperature of the hotbed and the drying time yourself. =  |

|

The warmth rises as the filament gets closer to the heat bed. As a result, flipping over the filament during drying is recommended for a better drying effect, as the filament will be dried more evenly (be careful not to burn yourself during the flipping process). |

- Choosing a selection results in a full page refresh.